|

SWINGARM

MAINTENANCE |

|

I

was doing other maintenance, and already had the wheel

off. Up until the time when the wheel is actually removed

and out of the way in this procedure, some of the text

will be saying one thing, while the picture kind of shows

another. The pictures are relevant, so have been included. |

If

you're going to remove the front countershaft sprocket

to replace it, or for whatever other reason, it would

be best to loosen the countershaft nut before proceeding

any further. This will make life easier later on.

It

is not necessary to remove the countershaft

sprocket if all you plan to do is lube the swing arm.

|

|

Lift

the bike so the rear wheel is off the ground. You'll have

to use a lift, or crate. Something like my Easy-Lift

won't work because you'll be removing the swingarm. |

|

|

The

order in which you do this, wheel or caliper doesn't really

much matter, but I prefer to remove the caliper first.

As shown above, remove the brake line holder. |

|

|

Next,

remove the caliper itself by taking out the mounting bolts,

shown in the picture above, marked by red dots. I suggest

removing the bottom bolt first, and then holding the caliper

as the top bolt is removed. |

|

|

Hang

the caliper out of the way, or place it on something like

a 5 gallon pail - don't allow it to just

hang by the brake line. |

|

|

The

picture above is from the Sharkfin

procedure, but shows the place where you should be now,

if you're following along with my text.

To

avoid re-adjusting your chain, loosen the axle nut,

and remove the axle. Slide the wheel forward until you

can take the chain off the rear sprocket. Then, remove

the wheel.

Oonce

you have the axle bolt removed, I would suggest a light

coat of grease to protect it, and make subsequent installation

and removal easier.

|

|

|

Next,

remove the engine sprocket cover. The position of the

three bolts to be removed are marked by the red dots.

|

|

|

NOTE:

It is NOT necessary to remove the countershaft sprocket

if you have no other reason for doing so.

Remove

the countershaft nut. Once the nut is off, you'll be

able to easily remove the sprocket and chain from the

shaft because the rear wheel is off. Put the nut, lock

washer and sprocket aside. The chain will eventually

be removed along with the swingarm.

|

|

|

Shown

in the picture above is a hose holder fastened to the

upper right corner of the swingarm. You can just loosen

this and take the hoses out, slip the hoses out without

loosening at all, or remove the bolt and holder all together.

It's easiest to just take the hoses out. |

|

|

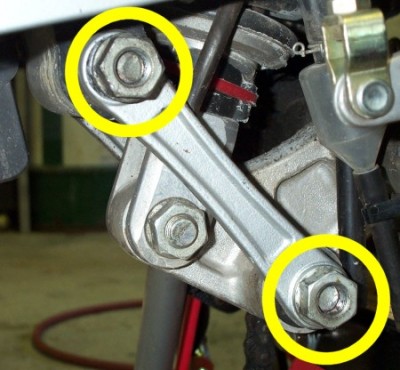

The

picture above shows the two links that will have to

be removed. (These are the pieces you'd replace if you

wanted to lower your bike.)

Order

doesn't really matter, but I remove the top bolt, and

then the bottom. Both are removed to gain access to

the swingarm and bearings (upper) and bearings (lower).

|

|

|

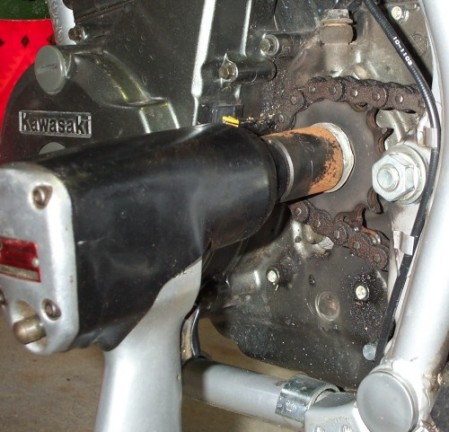

Next

is to remove the main mounting bolt. This one can be

troublesome if you've neglected to perform this service.

There are a multitude of options; some people just whack

the bolt end with a mallet, or, as I suggest trying,

with the nut removed, put an impact socket on the bolt

head and let it hammer away until the

bolt breaks free of the corrosion.

Additionally,

some people feel that the upper engine mounting bracket

should be removed to facilitate removal and/or installation

of this bolt. I've never done that, and have never had

any trouble whatsoever with the bolt. I believe this

is very unlikely, but if you simply can't get the bolt

back in, try loosening that upper engine bracket.

|

|

|

WARNING!

Be careful as you remove this swingarm mounting bolt.

As you can see in the picture above, as the bolt is removed

it can push against the brake pedal spring. It's possible

that no damage would occur, and that the spring would

just slide off the bolt head, but why take the chance!?

Just move it to the side, and out of the way. |

|

This

mounting bolt is the final thing holding the swingarm

in place. I sit behind the bike, with the swingarm on

my knees. I reach over and pull out the mounting bolt,

enabling me to "catch" the swingarm as it comes

away from the bike. It isn't at all heavy. |

|

With

the swingarm free of the bike, you can now remove the

swingarm and chain together. Now is a good time to drop

the chain into a bucket of WD40, kerosene or whatever

you want to use to clean it. Doing it now gives it time

to soak while you're taking care of the bearings. |

|

|

|

There

are four areas where the bearings are to be found, as

shown in the two pictures above. They are the two ends

of the swingarm, and in the middle underneath where the

top of the links connected. The fourth is part of the

shock mount, and where the bottom of the links connected. |

|

|

The

rubber seals are not difficult to remove, but care should

be taken to not damage them.

NOTE:

The shaft can be removed before the seals, this makes

getting the seals out easier. You can slip a thin blade

between the seal and the housing and rock it back and

forth slightly to loosen the seal. Alternatively, you

can put a screwdriver up into the seal from the outside,

and gently pop it out that way.

|

|

|

The

picture above shows the shaft and seals. All bearing locations

have this arrangement, but the shafts are shorter on the

two swingarm ends. |

|

|

Above

is a closeup of what you'll find. This is the middle,

underside of the swingarm, and there is a pair of needle

bearings in the housing. The bottom link / shock mount

housing has the same setup. The end of the swingarm has

just one bearing each. |

|

|

Remove

the bolt at the bottom of the shock. You can do this without

fear; the preload / spring tension is kept within the

confines of the upper and lower keeper plates, and won't

cause trouble now, or when it's time to reinstall. |

|

|

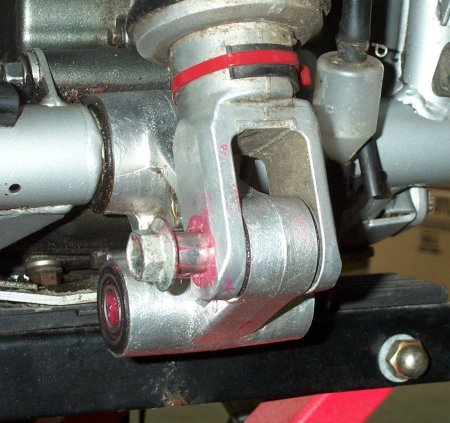

Remove

the gray caps on either side of the bike, (circled), and

then remove the bolt. I had to use a very long screwdriver

to tap the bolt all the way through. |

|

|

This

is what I found when the bolt was removed. It came out

alright now, but in another couple years I bet it would

have caused some real trouble. I cleaned it up, and greased

it before reinstalling. |

|

|

I

pumped the ends full of grease, and then reinstalled the

bolt - catching the grease at the other end as it was

pushed through. |

|

I

generally don't attempt to flush out the bearings in any

way. I use a lint-free rag to wipe out as much grease

as possible, and then just re-grease with a grease gun.

I fill the "hole" with grease, and work it around

as much as I can with my fingers. When I insert the sleeve

or bolt, I catch the grease as it's pushed through. |

|

Any

good quality grease would be fine; check out

Grease

101 if you need some info on choosing a

grease. I use Mobil synthetic grease.

I

take a gob of fresh grease on my finger, and work the

grease into the bearings as thoroughly as possible.

You can't really put in too much, the shaft will push

out any excess. The one area that should be relatively

free of grease is where the seal is seated. Much grease

here will prevent the seal from settling flush and completely

.

|

|

That's

pretty much it for the swingarm service. |

|

Clean

and lube the chain, and prepare it for reinstallation.

|

|

With

the chain over the left corner of the swingarm, put

the swingarm into place and insert the mounting bolt.

I do this the same way as I remove it; seated behind

the bike with the swingarm on my knees to help hold

it in place while I insert the bolt from the side.

The

swingarm mounting bolt nut takes 98 N-m, 10

Kg-m, 72 Ft-lb of torque.

|

|

Install

the two links. The nuts require 98 N-m, 10 Kg-m,

72 Ft-lb |

|

However

you chose to deal with it, make sure the hoses are secured

back into the holder at the upper right corner of the

swingarm. |

|

Loop

the chain around the (front) engine sprocket, and reinstall

the nut, and lock washer if used. (The Sagebrush

prevailing nut doesn't require the lock washer.)

The

engine sprocket nut takes 98 N-m, 10 Kg-m, 72

Ft-lb of torque.

|

|

Lift

the wheel up into place, and insert the axle bolt. The

axle nut requires 93 N-m, 9.5 Kg-m, 69 Ft-lb

of torque. Be sure to install the cotter pin. I use a

hairpin, with a ziptie around the two legs to be sure

it doesn't come out. |

|

Install

the brake caliper, and line holder. The brake caliper

mount requires 25 N-m, 2.5 Kg-m, 18 ft-lb

of torque. The brake line holder should just be snug.

Both the caliper mounting bolts, and the line holder should

have a little blue Loctite applied to them. |

|

Lower

the bike down to the ground, and adjust the chain, if

necessary. Remember to check the chain "loaded."

You can have someone sit on the saddle while you adjust

the tension, which is the easiest. It's a little more

hassle because you have to go back and forth, but you

can also lay across the saddle, or sit on the saddle to

see where you are. Make sure to do this though, there

is a big difference between loaded and

unloaded chain tension. And, unless you and your gear

don't weigh anything, loaded tension is the only one that

matters. |